TECHNILAINE is available

- in rolls (density 25 or 20kg/m3 only)

- in panels (25 and 80 kg/m3)

Hemp wool® Technilaine® have to be implemented in a healthy, dry and ventilated area. Technilaine® implementation and rock wool implementation are the same, but with a vapour retarder in the warm side. Technilaine® is always recommended with a vapour retarder in all implementations. The water vapor transmission rate for materials have to be higher outside than inside your home to let the vapour cross the wall.

How to cut TECHNILAINE®?

Compress the material between two wooden planks and You can use an angle grinder with an iron grinding wheel or with an diamond grinding wheel (work on rocks) to do this or a specific sharp knife for insulation. Depends on TECHNILAINE® density, the width will change : with a density of 20, 25 et 30 kg/m3 : cut 2 cm more than the empty spaces on the framework. The dentest material you use the smallest margin you need to cut.

the fitting of sheathing around lagging

Let a gap between the insulation product and the masonry.

With a wood backing frame : Technilaine® can be stapled each 25 cm on the framework.

with steel framework : Technilaine® will be implement in the framework.

Prior to other things, use a double sided adhesive tape and fix it on the steel framework. Apply one side of the double-face adhesive tape and set up the vapour retarder. After this you can reach the air tightness with the floor and the ceiling with glue and others adhesives.

Insulation of walls with wooden framework

Technilaine® have to be stapled each 25 cm on the framework.

Cut 2 cm more than the empty spaces on the framework.

After this, stapled the vapor retardater on the wooden framework.

Use more wooden battents to protect the vapour retarder against electrical ducts

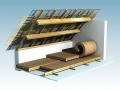

Technilaine implementation on a roof

rafler system in wood – insulation implemented – security

Let and air space between the under-roof or the rain cap and the insulation product. Use rolls or panels in two crossing layers implementation (it dépends on the framework of you project) or in 200mm in case of farmhouse roof. We suggest to apply from 200 to 240 mm of insulation products in roofs. The vapour retarder is fixed with staples and/or glue (depending on the type of framework: wood or steel) to reach a perfect air tightness.

to reinforce the stability of your work you can add twines in the framework .

CEILING IMPLEMENTATION

The vapour retarder is strongly recommanded in the warm side of the ceilling. For a efficient acoustic insulation between two levels we strongly advise a thickness from 100 mm to 200mm (rolls and panels density from 25 to 30 kg/m3).