Thermal insulation & acoustic insulation with hemp fibers

Thermal insulation & acoustic insulation with hemp fibers

Hemp wool® components

85% of hemp fibers

15 % of stable synthetic binder, non-emissive

Density

25 kg/m3 only in rolls 25 or 30 kg/m3 in panels high density of hemp wool® bring a higher thermal phase displacement: The heat takes more time to cross a dense material; in this way, your home stays fresh during the summer.

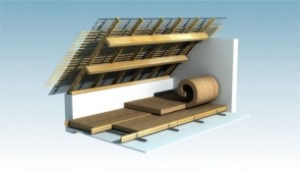

Use of hemp wool® TECHNILAINE®

- Roofs

- Attic

- walls (partitions)

- suspended ceilings

- Internal wall partitions

- Yurts insulation

Advantages of hemp wool® TECHNILAINE®

- Acoustic and thermal insulation

- Moisture management/Breathing wall

- Resistant to rodents and insects

- High mechanical strength

- Great durability

- Easy implementation

- Healthy and ecological product

- Dry thermal conductivity : λ =0.040 W/m.K

- Wet thermal conductivity : λ =0.048 W/m.K

- Specific heat in 25kg/m3 : 1370 J.kg.K

- Thermal phase displacement in 20 cm (25kg/m3) : 4h15min

- Tensile strength (parallel to the fibre) (NF EN 160812 – CSTB) : can bear twice the product’s weight.

- Tensile strength (perpendicular to the fibre) (NF EN 1607) : 4171 N/m²

- Reaction to fire classification : Euroclass F

- Water absorption (EN 1609) : 3.70 kg/m²

- Partial Humidification (ACERMI) : No dimensional changes

- Water vaporresistance (EN 12086) : μ = 1

- Sound absorption coefficient in 25kg/m3 (EN ISO 354) : αw = 0.65

- Transmission loss (partition 96/70 with wood R25.060) : Rw = 41 dB

- Biological resistance (CUAP) : F3 Storage : dry, safety from elements